Pharmaceutical tablet crush and break strength

Solution

- Software-controlled compression tester or texture analyzer

- Appropriately-rated loadcell for expected maximum load range

- Fixtures to crush or snap small, brittle products

Benefits

- Repeatable test method using a software-controlled texture analyzer

- Multiple test types performed by interchangeable fixtures on the same system

- Quantified fracturability and hardness results indicative of dispersion properties and general resilience resulting from formulation changes

Requirement

Many products come in tablet form, with a durability designed for both packaging and for use. Too brittle or too hard, and they may not be fit for use, or at best perform below expectation. The only way to determine consistency is mechanical testing of samples.

As a quality control measure on the production line, or as a manufacturing design tool, computer-controlled mechanical testing, based on criteria determined for an acceptable range of measures, is the only reliable method.

Measuring the physical strength of a pharmaceutical tablet enables the effect of formulation changes to be quantified. The product must still disperse and dissolve effectively in conjunction with functional resilience.

So what does it take to crush or break a tablet product?

Solution

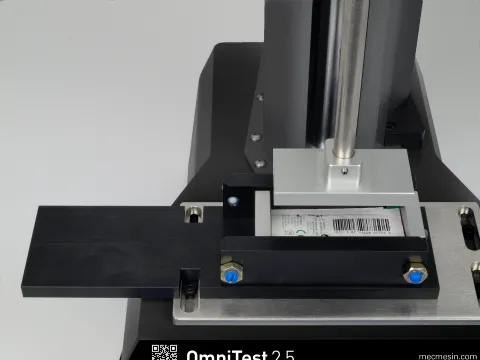

In this test, a Texture Analyzer (compression tester) was fitted with a 500 N intelligent loadcell and 1.5 inch (38 mm) cylinder probe. A short program advanced the probe to touch the tablet sample before advancing a further 1 mm, as sufficient to always break the sample. The controlling software also allows for break detection to stop the probe advancing further than necessary. The probe then returned automatically to the starting position.

The graphical representation of the test results for the samples (force applied, against cumulative displacement) clearly indicates the peak at which fracture initiates. The critical factor is the initial yield point of the tablet sample. This trace also profiles resistance from the fragments as the probe continued to crush downwards.

By switching to a different fixture, in this case, a three-point bend jig, a notched tablet may be tested for break resistance. This simulation of a user breaking the tablet (to swallow) quantifies the effort required against the formulation of the tablet itself, which must prove resilient to loads incurred during packaging, transit and storage.

The break point of many tablet products is a balance between resilience to the point of use, and viability in use. Frequently the tablet size denotes a required dose, whether it is a vitamin or a dishwasher additive, and nobody wants either a quarter mint in the bottom of a packet or a whole one that is too hard to crack. Other factors are important, including the pattern of breaking, but the crush strength is a primary indicator of manufactured quality. Mechanical attribute testing as shown here is reliable and repeatable. The method allows for any minor size variations, and provides a clear profile of the initial break. Careful initial testing of a product can produce upper and lower tolerance levels for the required break force, and be used for quality monitoring on the production line, producing instant pass and fail indication. Any drift towards failure can be fed back to the line, saving time and cost.

Test equipment

- Software-controlled Texture Analyzer or compression tester

- Perspex compression probe for crush

- Mini 3-point bend fixture for snap