Medical guidewire break strength test

Solution

- Motorised tensile tester

- Digital force gauge with data output capbility

- Wire grips designed for specific product testing

Benefits

- Quick and reliable testing to international standards

- Data capture for further analysis and audit trail

Requirement

The company is a manufacturer of wire formed medical devices and components, used within minimally invasive devices for cardio, endo and neurovascular applications. Medical guidewires are used for catheter insertion, catheter exchange and cannulation of vessels. It is therefore vital these guidewires perform correctly and must conform to British Standard BS EN ISO 11070:1999, which requires guidewire welds to be tested to determine their break strength.

Solution

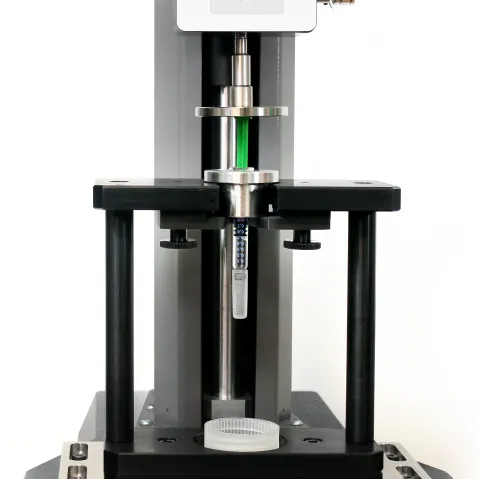

Mecmesin provided a VersaTest motorised test system and a Basic Force Gauge (BFG). The company used pneumatic test jaws, whilst performing the tensile load. To undertake this measurement, the test jaws are fixed to the VersaTest base plate and force gauge. The guidewire is clamped between them with approximately 8” (approximately 20cm) of space dividing the top and bottom test jaws. Once the test is initiated, the crosshead on the system moves the top test jaw upwards at a speed of 2” (approximately 5cm) per min ±10%.

The guidewire weld breaks and the maximum force is recorded on the force gauge. Once the crosshead reaches its limit point it returns to the starting position ready to begin the next test. The peak load is then transferred into Microsoft® Excel for further analysis. The simplicity of the test system coupled with the fact the test required minimal operator involvement convinced the supplier to purchase this product from Mecmesin.

Test equipment

- VersaTest (superseded by the MultiTest-dV series)

- Basic Force Gauge (BFG) 200 N

- Pneumatic test jaws