Syringe testing to ISO 11040-4 Annex G2 closure leakage

Solution

- Software-controlled compression tester

- Special fixtures to locate and load a selection of syringe barrels

- Fixture to hold a suitable receptacle for leaked fluid

Benefits

- Flexible and efficient equipment to repeatedly test to the relevant standards

- Upgradable accessories to extend the test capabilities

Requirement

The ubiquitous syringe is an extremely important medical device, delivering (parenteral) injectable products to the patient by means of a cylinder and plunger mechanism. To ensure safe use of an injectable medication, prefilled syringes for single use were developed to avoid the need to transfer the product from its supplied container into a hypodermic re-fillable syringe—a time-consuming process with potential for contamination.

The medical devices and pharmaceuticals sector is highly regulated, driven by compliance and auditing processes and all syringes need to perform precisely to specification. The needle shield closure system to must also play its part in ensuring the injectable remains sterile up to the point of administration .

Our customer required a test system to meet ISO11040-4 (Glass barrels for injectables and sterilised sub-assembled syringes ready for filling). Annex G covers the Test methods for closure systems, and G2 specifies Closure system liquid leakage test. This test is used to assess the liquid leakage resistance of the closure system to verify whether it can withstand any potential overpressure inside the syringe during the filling process or during transportation. The method applies a representative test pressure of 110 kPa, selected by the standards body based on process conditions during the fill finish process.

Solution

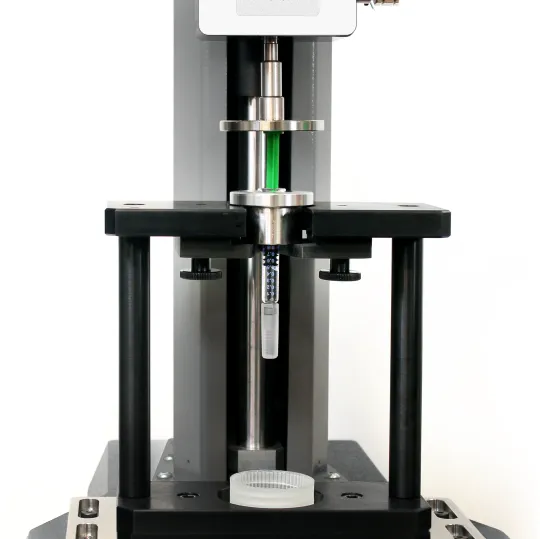

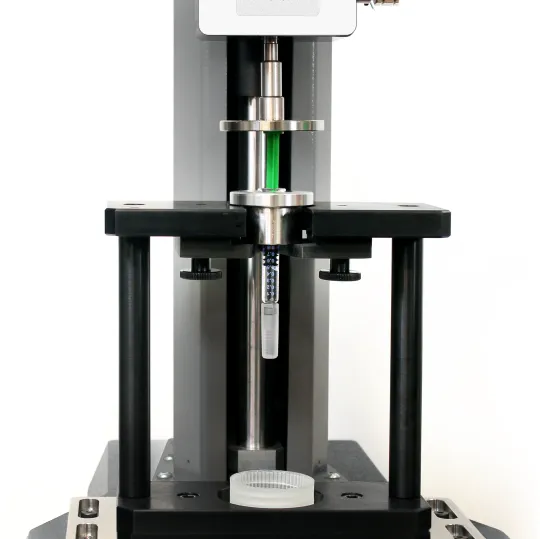

Mecmesin supplied a software-controller universal tensile and compression testing machine with appropriate loadcell capacity, crosshead speed control and data sampling rate, as indicated by the test standard. The customer provided a selection of syringe specimens, and our Special Applications team manufactured the fixtures to perform the closure system leakage test.

A small compression probe—to apply force to the plunger flange—depresses the plunger in a controlled manner, expelling distilled water (or other suitable reagent). This pressurises the needle shield or tip cap/barrel assembly exposing any potential failure in sealing. A formula relating to barrel volume and inner diameter calculates a force in newtons to hold for a 5 second duration. The test sample is then inspected for visible signs of leakage.

The Interchangeable components in the fixture enabled the customer to test various syringe configurations and also run other tests referenced in the standard.

VectorPro software runs with Mecmesin’s OmniTest UTM range and is built on an architecture which supports FDA 21 CFR 11 compliance by implementing Active Directory security control for seamless user management, and can deliver a complete testing audit trail, providing confidence in data integrity and security within a business in this sector.

Test equipment

- Software-controlled compression tester

- Special fixtures to locate and load a selection of syringe barrels

- Additional auxiliary fixtures are available for other Annex procedures to this standard, all fitting the holder frame