Furniture webbing tensile strength test

Solution

- Software-controlled force test stands

- Selection of fixtures for compression and tensile loads

Benefits

- Critical components of whole product tested for overall performance

- Programmed routines to repeatably perform multiple tests

Requirement

Supported by the Royal Household of Windsor Castle, a Buckinghamshire New University student was investigating the wear and strength properties of traditional English jute-based webbing, used in the construction and restoration of chairs and sofas, and a specially-commissioned linen webbing. The Royal Household wanted an evaluation to confirm that the linen webbing was indeed, the best choice of material, as the jute webbing was considered to have a reduced life span when exposed to continual wear within a working space.

Comparisons between samples made of the same material were also needed to ensure comparative analysis and statistical validity.

Solution

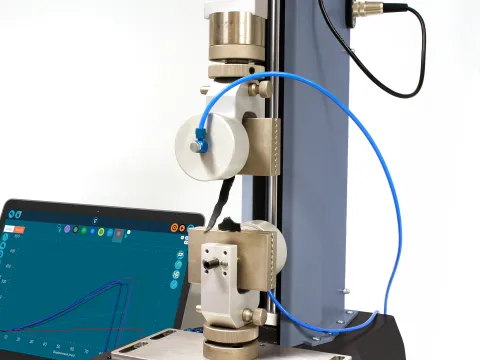

The customer created their own test jig replicating the structural frame of a seat, enabling the first test to mimic the action of someone sitting down. The jig was designed to impose a controlled amount of wear within the sample prior to the tensile test. Mecmesin provided a MultiTest 2.5-i computer-controlled test frame, in conjunction with an Intelligent Load Cell (ILC) and ball probe.

Samples of webbing were cut to size and stretched across the test jig. Once fixed in place, the system was programmed to move the ball probe affixed to the load cell, downwards, to a specified distance, placing a compressive pressure upon the webbing, and exposing the material to friction, where the webbing moves across the test jigs surface.

The ball probe is raised and lowered on a repetitive cycle several hundred times on each sample of material. This test is performed on several pieces of jute webbing for comparative purposes, and subsequently, on the linen-based equivalent to highlight the differences between the two webbing solutions. Once this assessment was complete, a further test was performed to establish the tensile strength of the webbing materials. Webbing samples, subjected to the first compression test, were also included to identify how, if at all, this had affected their strength. To identify peak tensile strength, new and pre-tested samples were placed between quick-release wedge grips and gradually tensioned until the material failed.

The linen based webbing was found to be significantly stronger than the jute webbing and showed negligible difference between new samples and those that had been pre-tested.

Test equipment

- MultiTest 2.5-i - rated to 2500 N

- ILC-S 1000 N

- Ball probe

- MultiTest 25-i - rated to 25 kN

- ILC-S 25 kN Wedge grips