Diamante pull-off test

Solution

- Motorised tensile test stand and gauge

- clamping fixture and slotted gripping accessory

Benefits

- Approved product quality testing to customer specification

- Simple and reliable test procedure

- Test To Failure (TTF) condition detected and captured automatically

- Confidence in meeting safety standards

Requirement

The customer was a supplier to major UK clothing retailer Marks & Spencer, who stipulate that all fasteners and attachments must be tested to failure.

The strength of the joint/diamante was critical to ensure that it met the design tolerance and safety levels. A motorised unit with a test speed was defined at 200 mm/min as the system needed to be simple to use in a production environment and provide consistent results.

Solution

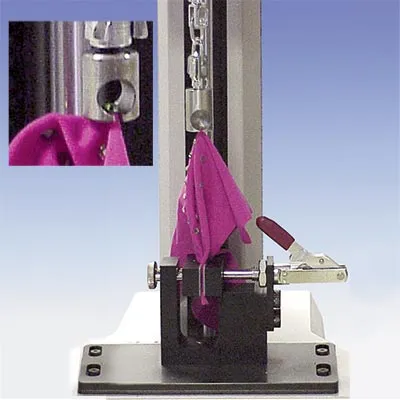

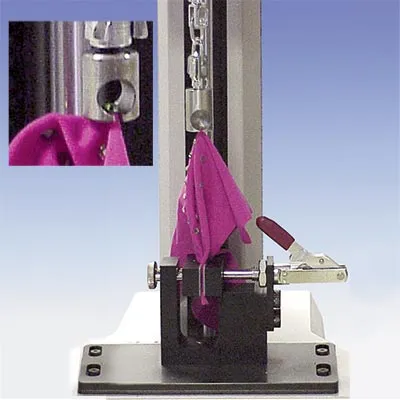

The cloth material was clamped in a 'Double Action Vice Grip' with 50 mm wide faces coated with non-slip rubber to enhance the gripping strength. The diamante attachment was loaded from the front into a slotted claw fixture, ready for testing.

For ease of loading the diamante into the fixture and also to help maintain a straight-pull, the 'Diamante Fixture' was connected to the force gauge via a flexible chain link. The peak tension load to remove/break the diamante was recorded at the fast data-acquisition speed of 1200 Hz.

Test equipment

- 1000 N UltraTest Motorised Test Stand

- 500 N AFG

- Diamante Fixture

- Double Action Vice Grip