TerraFixing's use of the Mecmesin OmniTest 25 for direct air carbon capture technology

TerraFixing, a leader in Direct Air Carbon Capture (DAC), uses Mecmesin’s OmniTest 25 to ensure the durability of its zeolite monoliths, which adsorb CO2 from the air. By testing mechanical properties like cold crushing strength to ASTM standards, TerraFixing ensures quality and reliability in scaling its climate-change solutions. The in-house testing capability, powered by Mecmesin’s VectorPro software, streamlines processes and supports TerraFixing’s mission to achieve global net-zero goals.

Testing our materials against industry standard methods is key for quality, repeatability, and durability, and so we are very pleased that The OmniTest 25 enables us to test our materials using ASTM and ISO compliant methods.

Vida Gabriel

Co-Founder, TerraFixing Inc.

TerraFixing is dedicated to combatting climate change through affordable and scalable Direct Air Carbon Capture (DAC). Their innovative technology is capable of capturing CO2 directly from the atmosphere, even in cold climates, which sets them apart in the industry. By utilizing DAC, TerraFixing aims to mitigate current CO2 emissions and reverse the impact of historical emissions, making a significant contribution to achieving global net-zero targets.

TerraFixing’s technological approach

Zeolite monoliths in DAC: At the core of TerraFixing’s technology are zeolite monoliths. Zeolites are microporous, aluminosilicate minerals with a high surface area, making them highly effective at adsorbing CO2 from the air. These materials are inexpensive and robust, and have been proven in industrial applications for over two decades.

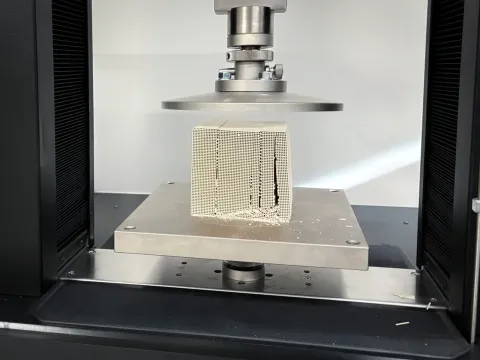

Monolith structure: The zeolite monoliths used by TerraFixing are specially designed structures that maximize the surface area available for CO2 adsorption. The monoliths are constructed from a composite of zeolite crystals and a binder that provides structural integrity. This design ensures that the monoliths can efficiently capture CO2 while maintaining the mechanical strength required for long-term operation.

Use of Mecmesin OmniTest 25

To ensure the reliability and effectiveness of their adsorbent materials, TerraFixing has integrated the Mecmesin OmniTest 25 universal testing machine into their testing regime.

Purpose of testing: The OmniTest 25 is used to test the mechanical properties of the zeolite monoliths that are critical to the DAC process. Specifically, the machine measures the cold crushing strength and modulus of rupture of these monoliths to ensure they can withstand the operational stresses in real-world conditions.

Standard compliance: Testing is conducted according to the ASTM C133-97 standard, which specifies methods for determining the cold crushing strength and modulus of rupture of refractories. This ensures that TerraFixing’s adsorbents meet stringent quality and durability criteria.

Why the OmniTest 25?

- Capacity: The 25 kN capacity of the OmniTest 25 is essential for testing large monoliths used in TerraFixing’s scaled-up operations.

- Precision and reliability: The machine provides precise measurements that are critical for characterizing the mechanical properties of the adsorbents.

- Powerful VectorPro software: Its integration with VectorPro Software enables users to set up, execute, and interpret complex test protocols effortlessly. Additionally, the software's advanced reporting and customizable test parameters streamline workflow efficiency, making it accessible for both novice and experienced operators.

- In-house testing: Previously, TerraFixing outsourced these tests. Bringing testing in-house allows for greater control, quicker feedback, and integration into the development process.

Testing Process

- Monolith preparation: Zeolite monoliths are prepared and subjected to mechanical testing using the OmniTest 25.

- Data collection: The machine measures the force required to crush the monoliths, providing data on their strength and durability. The Mecmesin OmniTest 25, integrated with the powerful VectorPro software, captures and analyzes this data. VectorPro allows for precise control and real-time monitoring during tests, ensuring accurate and comprehensive data collection. This software facilitates detailed reporting and analysis, helping TerraFixing to refine their materials and processes continuously.

- Quality assurance: Each monolith is tested to ensure it meets the necessary standards, with approximately 20 monoliths produced and tested monthly.

Implementation and benefits

“Measuring the structural integrity of our newly developed and proprietary zeolite structures is key in producing a robust and scalable DAC technology. Testing our materials against industry standard methods is key for quality, repeatability, and durability, and so we are very pleased that The OmniTest 25 enables us to test our materials using ASTM- and ISO-compliant methods. The Mecmesin team has been so helpful in helping us find the right equipment for our testing needs we’re excited to be using their equipment in our R&D labs and look forward to exploring different testing machines that we can use in our manufacturing line,” comments Vida Gabriel, Co-Founder, TerraFixing Inc.

The integration of the Mecmesin OmniTest 25 into TerraFixing’s workflow represents a significant advancement in their DAC technology development. By ensuring the mechanical integrity of their zeolite monoliths, TerraFixing can confidently scale their operations, contributing to the global effort to reduce atmospheric CO2 levels and combat climate change.