Search results

Mecmesin solutions for the food and drink sector.

We live in a world where the majority of food and drink products are supplied pre-packed in packaging that protects, but that is designed to be opened easily.

The sheer amount of single-use packaging and the growth in environmental regulations creates pressure to produce it with minimal waste and expense, whilst still making sure that it is fit for purpose. That is where physical testing of food & drink packaging becomes essential to ensure the customer experience is positive:

- Consumer food packaging needs to be peeled open so must be designed and checked for 'maximum seal and minimum peel'.

- Retort pouches require the consumer to overcome a pre-tear perforation whilst withstanding puncture forces to protect the contents.

- Plastic drinks bottles need to use a minimal amount of raw material yet still be able to withstand the forces applied during filling and stacking, so they need to be tested for top-load strength.

- Twisting opening a drinks cap or closure can itself be a challenge particularly for the elderly. Torque testing during the design and production cycle becomes critical to ensure usability and that the brand image is not harmed by poor packaging.

- Spray cans require the correct finger pressure to activate the aerosol. Ring-pulls must provide a secure seal but not require excessive opening force which breaks nails or cut fingers.

The list of applications is almost endless and the more packaging becomes aesthetic in itself, the more difficult it can be to grip and test.

At Mecmesin we design force and torque measurement systems and fixtures for testing packaging products of all kinds, so that you can apply industry standard test methods in both designs and on the production floor for quality-control.

Our Emperor control and analysis software is powerful and flexible for reliable, accurate, repeatable testing at the push of a button.

Test to your own company standards as well as to ASTM, BS EN, ISO, DIN, CEN, Afera, FEFCO, FINAT, PSTC, TAPPI and TLMI

Interested in texture analysis?

Mecmesin has over 40 years' experience in the design and manufacture of texture analyzers, texture presses and tenderometers. There's more to discover in texture analysis on our dedicated Texture Analyzers site (www.textureanalyzers.com).

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

Tethered closures testing attachment force

Wine can pop-and-tear opening force

Adhesive test on capsulated stoppers

Metal bottle cap on glass pull-off test

Peel testing vacuum-formed containers

Custom bottle cap mandrels

Cardboard beverage bottle carrier unfolding

Bulk liquid carrier closures

Tea bag integrity

Rotating Vacuum Peel System

ISBT sports cap rotational test

Wine cork extraction test to ISO 9727-5

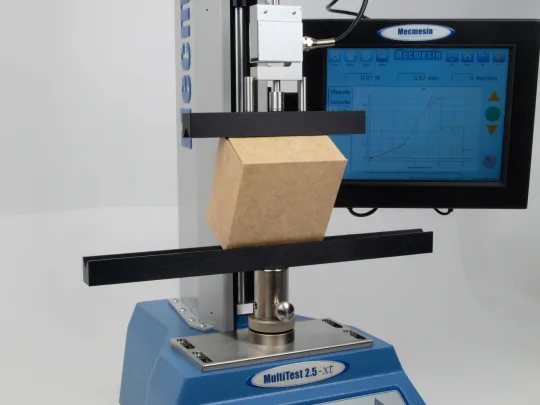

Fast food tray crush testing

Top-load testing PET bottles

Top-load crush test of plastic bottles

Pork pie penetration test

Tensile testing on polyethylene film

Tamper evident ring test

Coefficient of friction test on plastic film

Extraction testing of whisky stoppers

Sachet compression test

ISBT sports closure tension test

Torque to twist out a champagne cork

Screw-cap torque test on PET bottles

ROPP bottle cap closure torque test

ROPP Wine Closure Removal Torque

Simulate interactions with food, cosmetics and pharmaceuticals

Through texture analysis you can simulate any interaction with food, cosmetics or pharmaceutical products and measure the physical sensory experience.

This enables you to control production, ensure quality and optimise processing.

Discover more about texture analysis on our specialist application microsite - TextureAnalyzers.com.

![Suction fixture carton fold test, fully open position [PDV8017] Suction fixture carton fold test, fully open position [PDV8017]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2020-12/989-cardboard-beverage-tension-test-system.jpg.webp?itok=v-xgxcIO)

![Press-fit valve collars [PDV14192]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2020-12/1650-PDV14192-1-web.jpg.webp?itok=5HrBrRab)