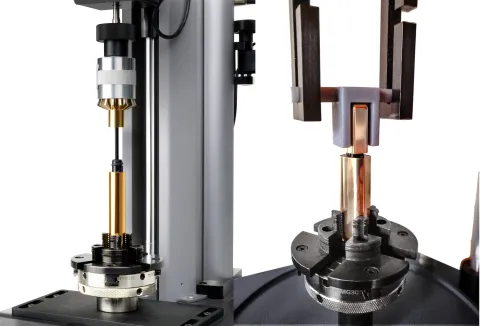

Pneumatic top-load control for CRC cap torque testing

Customised engineering example

Testing the opening torque of child-resistant bottle caps requires the application of a simultaneous downward force to overcome the safety mechanism. This axial downward force is applied by dead-weights during the testing process.

Repeatedly raising and lowering the dead-weights in a testing sequence is much easier, quicker and more secure when the process is automated. Our client wanted to eliminate the effort for operators to manually lift dead-weights. Mecmesin supplied a pneumatic lifting mechanism adapted for the client's Vortex torque test stand. It raised the dead-weights to allow a new specimen to be inserted into the Vortex test machine, and then smoothly lowered the torque head and weights onto the cap ready for testing.

By semi-automating the process our client was able to make batch testing quicker, more reliable, and less tiring for the operator to perform.

Our VortexPro and HelixaPro torque testing systems both have the facility to apply a downwards force to engage the mechanism inside a 'push and turn' closure. VectorPro software then plots the torque characteristics against angle to help analyse the rotary performance of the cap. Audit trail and event log features are available to adhere to 21 CFR Part 11 compliance within this software, its robust and secure database architecture and connectivity are designed for global pharma and medical devices sectors.