Cosmetics brush pull-out testing

Customised engineering example

Our client is a major cosmetics company using a variety of brushes, make-up wand and applicator designs for all applications and wished to tensile test the integrity of the bristles. The bristles themselves may be a mixture of filaments or plastic/rubber bristles for specific cosmetic product application.

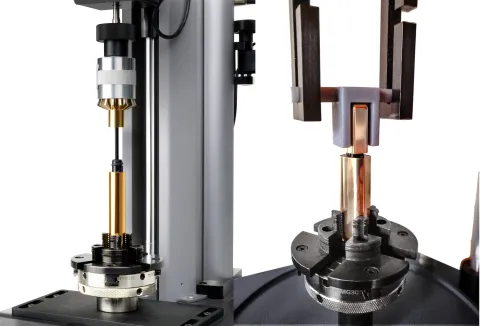

Gripping the awkwardly-shaped handles and bristle tips in a repeatable way, demanded more than a single standard vice grip.

Mecmesin's custom solutions team designed a system of overlapping plates with cutouts for each brush head profile. The plate served to gather and trap the bristles uniformly in a vice action so that they were axially aligned under the loadcell.

A lathe-chuck grip held the handle securely for reliable and accurate pull-off testing.

Repeatable testing

The interchangeable fixtures enabled the manufacturer to obtain repeatable and consistent results for all conceivable applicator designs. The cosmetics industry is fiercely competitive in terms of being design-led in its products and packaging solutions.

The size and shape of make-up brushes are engineered to enable effective application of the product irrespective of its physical texture and where the product needs to be applied. Precise application of eyeliner and mascara may require quite a differently shaped brush to a blusher, all must perform reliably and last through daily usage, without leaving individual bristles on the consumer's skin.