Headset microphone joint torque

Improving on the company's quality assurance processes and focussed on the swivel function of the microphone arm of its headsets. A customer's perception of the quality of the product is directly influenced by the activation torque on the joint to rotate the arm of the headset.

Solution

- Vortex torque tester featuring integrated software, a torque sensor and gripping fixtures

Benefits

- improved product quality

- production material cost savings

- reduced wastage

Since we initiated this sample testing procedure, we have improved the consistency and level of quality of our products. The intuitive graphical illustration of the results helps us better understand the whole test and the nature of the torque characteristics, which assist in the design process.

Daphi Dai, R&D Laboratory Manager

Jabra GN Netcom

Requirement

Jabra is a subsidiary of GN Netcom and is a global manufacturer of innovative headsets (wireless and corded) and speakerphone solutions. These products cater for mobile phone users and also office-based users, such as company contact and call centre agents.

The organisation’s research and development lab wanted to further improve its quality assurance processes and focussed on the swivel function of the microphone arm of its headsets. The activation torque on the joint to rotate the arm reflects in the customer’s perception of quality of the product.

GN Netcom produces a range of equipment and their internal standards are used to test lightweight components with expected torque values from below 0.3 N.m up to a maximum of 1.5 N.m for more robust everyday devices.

Solution

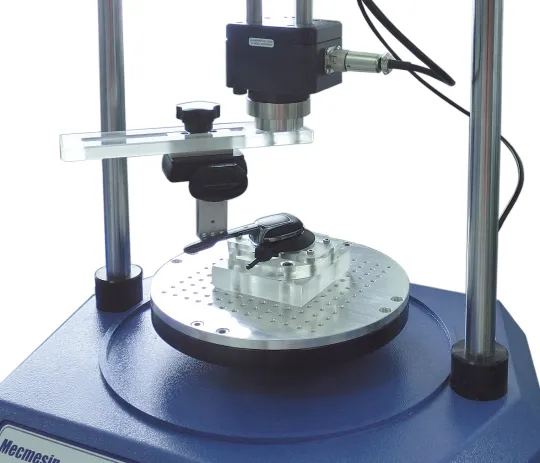

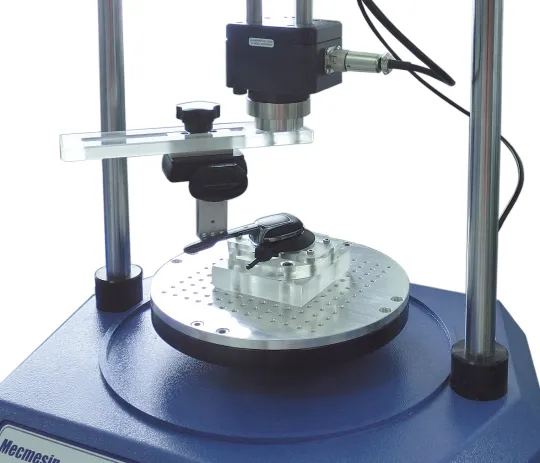

Mecmesin supplied a twin-column motorised and computer-controlled torque measurement system, including two crossheads with integral intelligent torque cells.

Each torque cell rating was appropriate to the type of headset being tested. The sample is located in the adjustable lower fixing plate, which rotates beneath an upper peg fixture to move the headset against the microphone arm, arcing through its full range from stored to deployed position, and back again.

Emperor™ software controls the whole process via a library of test programmes, and the characteristics of the mechanism under the applied torque are displayed as a real-time graph.

The flexibility of the computer programs possible with the system is ideally suited to the research and development setting of GN Netcom.

The programming environment allows the test procedure to be easily modified for prototype headset designs, which can then be retained in the library and run at any time.

The company has seen an increase in the quality of their products, realised savings in production materials costs, and has reduced wastage.

Test equipment

- Vortex-i torque test stand, replaced by VortexPro with VectoPro

- 0.3 N.m intelligent torque cell

- 1.5 N.m intelligent torque cell

- Lower fixing plate with 4 adjustable pegs (10 – 190 mm opening)

- Custom aluminium upper fixtures, dependent upon the product design

- Company: Jabra (a GN Netcom company)

- Industry: Engineering

- Jabra is a global manufacturer and innovator of headsets and speakerphone solutions. A subsidiary of GN Netcom Jabra cater for mobile phone users and contact centre agents.

Company website