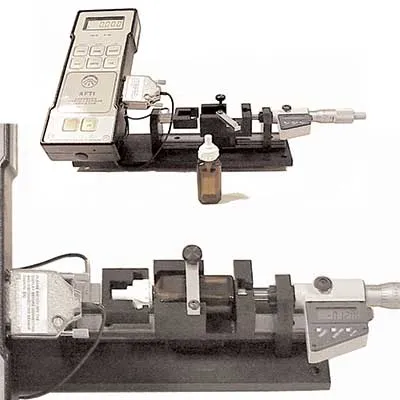

End float test of inhaler cap

Solution

- Custom testing station with digital display and matched loadcell

- Bespoke-designed fixturing to locate and adjust the test specimen precisely

Benefits

- Simple and quick test to exact internal standard

- Reliable procedure with adible and visible load indication

- Confidence in quality testing new and innovative designs

Requirement

'End float is the displacement in mm of a product', in this case the dispensing cap closure of the inhaler measured at a specific load.

The customer wished to apply a 3 N load in both tension and compression to the cap of a new design of inhaler.

Any resultant displacement from the normal position then had to be measured.

Solution

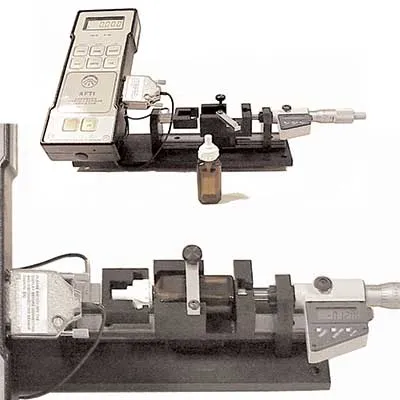

The sample was laid horizontally into a slide-mounted nest and clamped into position.

The cap of the bottle was rested in a location fixture connected to a 5 N S-beam loadcell.

The nest was incremented forward using micrometer adjustment until a minimal compressive load was achieved, displacement at this load was zeroed.

The nest was then moved forward until a 3 N alarm point was reached and the displacement of the load was noted (compressive end float).

For the calculation of the tensile end float, the process was reversed.

The system was supplied with mechanical limit stops to prevent accidental overload of the small capacity loadcell. The use of both tension and compression visual and audible alarms provided a clear indication of when the test load had been achieved.

Test equipment

- AFTI Advanced Force and Torque Indicator

- S-Beam Junior Loadcell 5 N

- Slide Mounted Rest

- Location Fixture

- Micrometer Adjustment Barrel

- Base Plate

- Company: GlaxoSmithKline

- Industry: Medical and medical device

- GSK are a science-led global healthcare company, active in the research, development and manufacture of innovative pharmaceutical medicines, vaccines and consumer products.

Company website