Automotive chain drive components tension and compression testing

Solution

- High-capacity software-controlled universal testing machine

- 50 kN ELS loadcells

- Customer's unique grips and fixtures for their own test methods

Benefits

- Improved testing consistency

- Enhanced data accuracy

- Increased operator safety

- Operational efficiency

Requirement

Tsubakimoto Automotive (Thailand), a leading manufacturer of industrial chain drives, attachment chains, and large-size conveyor chains, recognizes the critical importance of component durability and functional performance of these power transmission products to maintain their high standards.

There was a requirement to achieve consistent and repeatable test results, enhancing the reliability of quality control processes. Tsubakimoto have their own internal strength and durability standards in addition to industry requirements and the ability to implement these procedures to leverage their own unique experience repeatably was vital.

Several testing scenarios needed to be accommodated. Tensile testing methods ensure that the chains can withstand the forces they will encounter during operation without undue elongation or breaking. Compression methods verify the chains' ability to endure compressive forces, preventing deformation and ensuring consistent performance.

Solution

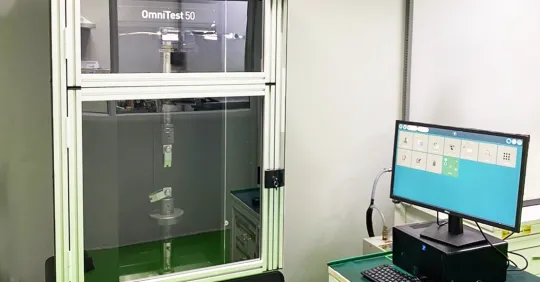

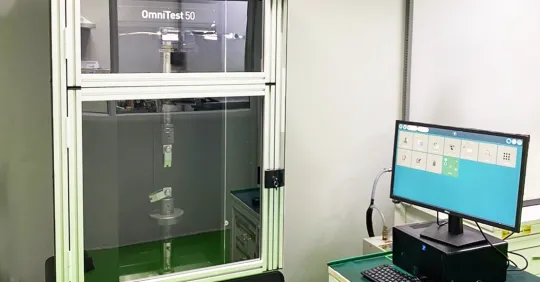

Mecmesin supplied a high-capacity twin-column UTM, rated to 50 kN of force. This robust testing machine offers precise and reliable tension and compression testing and can evaluate the strength and durability criteria of a wide range of chains. VectorPro software ensures accurate data collection and analysis, allowing Tsubakimoto to monitor and improve product quality efficiently. Its intuitive interface and advanced features which integrate with the hardware, allow custom programs to be written to the company’s standards to provide an invaluable tool for their quality control processes.

The safety guard is an essential feature for this application, providing a safe and secure environment for operators during testing, preventing potential accidents or injuries.

This integrated system streamlines the testing process, allowing Tsubakimoto to maintain high production rates without compromising on quality. VectorPro software provides precise data analysis, enabling Tsubakimoto to meet their own, and exceed industry standards.

Mecmesin's advanced testing solutions have enabled Tsubakimoto to enhance their quality control processes significantly. The combination of the twin-column OmniTest 50 kN, VectorPro software, and safety guard ensures their chains meet the global standards of strength and durability while maintaining a safe and efficient testing environment.

Test equipment

- OmniTest 50 kN twin-column tensile/compression universal testing machine

- VectorPro software

- High-quality interlocked fitted safety guard

- Company: Tsubakimoto

- Industry: Automotive, Engineering

- Tsubakimoto manufacture and supply various variable speed drives and related parts