Catalyst crush strength tester, configured for key international test standards including ASTM D4179 and ASTM D6175.

ASTM D4179 covers the measurement of compressive ‘side crush strength’ (SCS) of single pellets in a regular form, such as spheres, short cylinders or tablets, while ASTM D6175 covers the measurement of compressive ‘side crush strength’ (SCS) of single extruded catalysts of 1.6 – 3.2 mm diameter having a length to diameter ratio of ≥ 1:1.

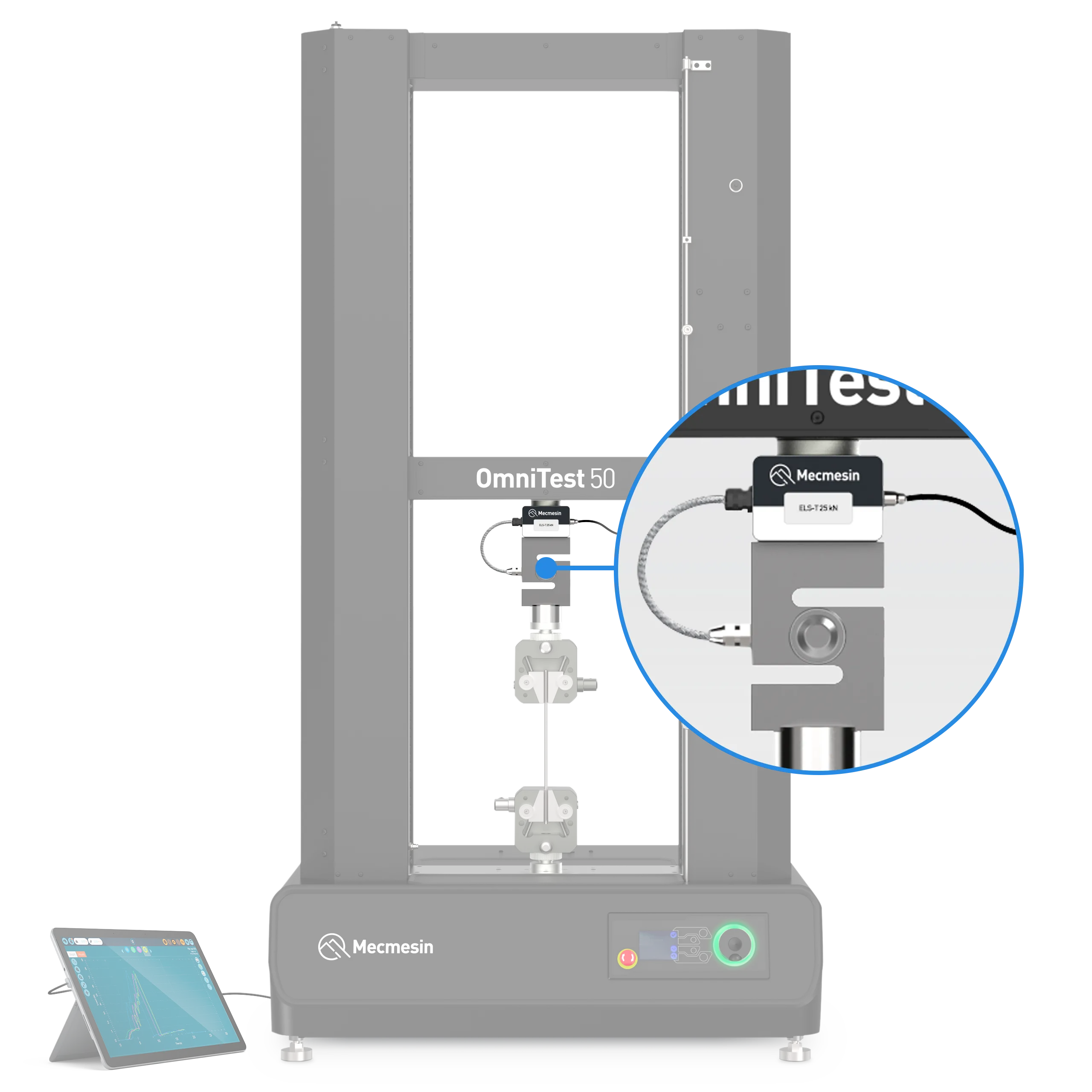

The OmniTest universal testing machine is ideal for performing single pellet crush strength testing, and can be configured with additional fixtures for performing bulk crush strength testing of catalytic material.

Emperor™ Software

VectorPro® software

VectorPro is our advanced force testing software package developed to perform tensile, shear, bend and compression tests on materials, components and products. Present measurement data graphically and share customised test reports quickly.

Simply choose an ELS loadcell and a set of grips, and you are ready to enjoy enhanced testing with the power of VectorPro.

Key features

Design

Intuitive icon-driven interface and workspace

Advanced 'drag and drop' test routine builder

Personalised user accounts and favourites

Touch screen enabled

Control

Stress/strain machine control

Active or basic load control

System deflection compensation

Manage user permissions and audit trail

Report

Built-in data calculations

Customisable test report templates

Print results to Adobe PDF format

Export data to Excel and other data packages

OmniTest test frame

A single-column motorised test frame designed to apply tensile, shear, flexural and compressive forces from

Its versatile construction makes it perfectly suited for testing all kinds of materials in a quality control or R&D environment.

Test frame

The single-column OmniTest features a ballscrew-driven motorised test frame, which is designed to apply tensile and compressive forces from 2N right up to 7.5 kN.

A dovetailed crosshead design ensures operators can quickly and easily attach new loadcells, that are automatically recognised by the software.

The base plate of the OmniTest is pre-drilled with threaded holes to directly accept a wide range of grips and fixtures.

Its versatile construction means that the frame has enough daylight to accommodate tall specimens and enough travel to measure the tensile strength of the most elastic of materials.

Connect your computer

The OmniTest requires a Windows PC to run the VectorPro MT software and control the tensile tester. Its compact design and small footprint make it the perfect selection as a bench-top device.

Optional console

Alternatively, a Windows-based touchscreen console can be mounted directly on the OmniTest - save time by not moving to and from a computer.

Sensors

The OmniTest universal testers use Mecmesin's range of high-resolution precision Enhanced Load Sensors (ELS) to record tensile and compressive loads.

ELS

A precision loadcell connects directly to an OmniTest or MultiTest-dV stand and communicates with VectorPro MT software, enabling sophisticated test routines for materials testing applications.

Enhanced Load Sensors (ELS)

The ELS range of interchangeable tension and compression loadcells is specially adapted to the OmniTest universal testers. They can also be used when upgrading a MultiTest-dV stand to become a MultiTest-dV(u) materials tester.

To ensure that you have the optimum selection to meet your tension and compression testing needs, eighteen different models are available to cover the range from 2 N right up to 50 kN.

Loadcell capacity, range and accuracy

Each loadcell reads from zero to its full nominal capacity and is accurate to ±0.5% of reading from 2 - 100% of range. Class 0.5 according to ISO 7500-1

Each sensor is delivered as standard with its own calibration certificate traceable to national standards.

Servicing and calibration

Mecmesin also provides annual servicing and loadcell re-calibration. Talk to one of our engineers or your local national distributor to find out more.

ELS (2 - 500 N)

The ELS comprises a sturdy dovetailed-mounting box with an internal loadcell, complete with a small fixing thread and occupies minimal space.

ELS-S (100 N - 5 kN)

The ELS-S comprises the same dovetailed-mounting box with an external S-beam loadcell situated beneath. It provides a more rigid secure connection for large, heavy grips and fixtures than the ELS.

ELS-T (7.5 - 25 kN)

The ELS-T comprises a mounting box with an external S-beam loadcell situated beneath. It is designed for use with the OmniTest 7.5 and the OmniTest twin-column test frames for the testing of higher loads and provides a rigid secure connection for large, heavy grips and fixtures.

ELS-P (20 - 50 kN)

The ELS-P comprises a mounting box with an external Pancake loadcell situated belneath. It is designed for use with the OmniTest 50kN twin-column test frame for testing of higher loads and provides greater immunity to extraneous "off-axis" loads.