The HelixaPro is a precision torque tester controlled by VectorPro software running on your computer. Designed for challenging applications where torque forces may be very small and accuracy is the priority.

The HelixaPro is easy to use and, when combined with application-specific fixturing, it is the optimal solution for measuring torque from 1 mN.m to 6 N.m.

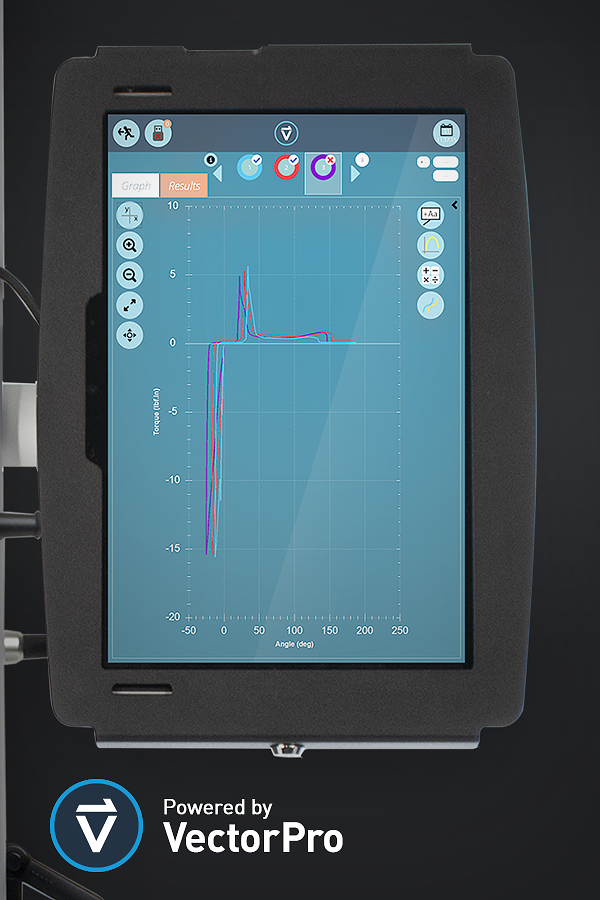

The HelixaPro Touch is a top of the range torque tester controlled by a touchscreen console running VectorPro software. Designed for challenging applications where torque forces may be very small and accuracy is the priority.

The HelixaPro Touch is easy to use and, when combined with application-specific fixturing, it is the optimal solution for measuring torque from 1 mN.m to 6 N.m.

The HelixaPro is a precision torque tester controlled by VectorPro software running on your computer. Designed for challenging applications where torque forces may be very small and accuracy is the priority.

The HelixaPro is easy to use and, when combined with application-specific fixturing, it is the optimal solution for measuring torque from 1 mN.m to 6 N.m.

Got a question about a product? Your local representative is...

Mecmesin/PPT Group, UK

Overview

HelixaPro and HelixaPro Touch precision torque testers

The HelixaPro is the perfect solution for measuring low and medium torque on a variety of delicate or finely-engineered products. Its innovative design features precision alignment and a counterbalance mechanism, essential for testing high-quality assemblies, such as those found in cosmetics, jewellery, electronics, pharmaceutical and medical industries.

Its versatile construction even allows for an axial force to be simultaneously applied whilst torque is measured - essential for products such as medical luer connectors and child-resistant closures.

Test frame

Precision automated torque tester

The HelixaPro and HelixaPro Touch feature a precision motorised test frame which is designed to apply torque from a few mN.m right up to a capacity of 6 N.m. Its high-quality construction, manufactured under ISO 9001 quality standards, ensures the ultimate in repeatable testing.

When seeking to precisely measure such low torque it is often crucial to make sure that no extraneous forces are applied to the test object during the test. The innovative design of the HelixaPro allows you to counterbalance the weight of a grip thereby removing its influence upon the object under test. An adjustable alignment tool ensures grips can be perfectly positioned on the centre-line to ensure torque is applied concentrically.

Its versatile construction even allows for an axial force to be simultaneously applied whilst torque is measured - essential for products, such as child-resistant closures, which require a mechanism to be engaged before they can rotate.

Make use of your own PC to run its software and take advantage of its small footprint to make it the ideal choice as your bench-top torque tester.

Torque sensors

Interchangeable sensors, from 0.1 - 10 N.m

A range of interchangeable ETS torque sensors are specially adapted to the VortexPro and HelixaPro. Connect a torque sensor to the test frame and the calibration characteristics are automatically recognised by the test system and software without any input from the operator.

Eight different sensors are available with nominal capacities ranging from 0.1 N.m up to 10 N.m. This ensures that you have the optimum selection to meet all your torque testing needs. Measurement accuracy is an outstanding ±0.5% of the sensor capacity.

Each sensor is delivered as standard with its own calibration certificate traceable to national standards.

Software

Powered by VectorPro™

VectorPro™ testing software is at the heart of our VortexPro and HelixaPro torque testing systems. VectorPro runs on any Windows computer, simultaneously controlling the motorised test frame and sampling test data at 20,000 Hz from the ETS torque sensor and angle encoder of the frame.

Step-by-step test routines can be quickly and easily created according to the exact requirements of your testing procedures. Configured tests are easily selected on the home screen with a single click or touch.

Real-time plotting of measurement data on an interactive graph enables the operator to identify precisely how the test specimen is performing. Pre-set calculations analyse the data and can determine whether the specimen has met the pass/fail criteria of the quality-control specifications.

At the end of the test, the powerful reporting module within VectorPro™ allows the operator to issue a test report as a PDF. Additionally, the data can be exported to Excel or to the network for further analysis by a Statistical Process Control (SPC) package.

Grips and fixtures

Standard fixtures and custom grip design

Holding your test specimen in place without it slipping is essential to obtaining repeatable results. Mecmesin has designed a range of torque grips to hold a variety of components. They include chucks and mandrels to hold plastic and metal closures, fixing tables to secure bottles and containers plus many more.

The varying nature of specimen sizes and shapes often makes it necessary to design and produce a special grip. Mecmesin's team of design engineers can work with you to develop the best grip for your specimen. These are then produced on our 3D printers to create lightweight, precision fixtures or, for higher load applications, they are made from metal at our machine-shop.

Emperor™ Software

VectorPro® software

VectorPro is an advanced torque testing software package developed to perform torque testing on components and products. Capture measurement data graphically and share customised test reports quickly.

Simply choose an ETS loadcell and grips or fixtures for your test specimen, and you are ready to enjoy enhanced testing with the power of VectorPro.

Key features

Design

Intuitive icon-driven interface and workspace

Advanced 'drag and drop' test routine builder

Personalised user accounts and favourites

Touchscreen enabled

Control

Torque/angle machine control

Active torque-hold and cycle functions

Manage user permissions and see audit trail

Digital I/O's for automation of testing

Report

Built-in data calculations

Customisable templates for test reports

Print or email test results automatically

Export data to Excel and other data packages

Torque sensors

The Enhanced Torque Sensors (ETS) range of interchangeable torque sensors are specially adapted for the HelixaPro and VortexPro test systems.

Plug and play for automatic calibration with availability to suit all requirements in capacities from

We also design customised solutions for applications requiring torque measurement up to

ETS torque sensors

The Enhanced Torque Sensors (ETS) range of interchangeable torque sensors is specially adapted to the HelixaPro and VortexPro test systems.

They plug into the frame of the precision torque tester and their calibration characteristics are immediately recognised by the software without any input from the operator.

To ensure that you have the optimum selection to meet all your torque testing needs, eight different sensors are available. All sensors measure from zero and cover the range from 0.1 N.m right up to 10 N.m .

A range of grips, fixing tables and chucks is available to hold your specimens. Connection to each ETS sensor is via a ⅜" male square drive (ETS 0.3 - 10) or via a ¼" female hexagonal drive (ETS 0.1 - 0.2)

Sensor capacity, range and accuracy

Each sensor reads from zero to its full nominal capacity (listed below). Measurement accuracy is an outstanding ±0.5% of the sensor capacity.

| Model ETS | 0.1* | 0.2* | 0.3 | 1 | 1.5 | 3 | 6 | 10** |

|---|---|---|---|---|---|---|---|---|

| N.m | 0.1 | 0.2 | 0.3 | 1 | 1.5 | 3 | 6 | 10 |

| kgf.cm | 1 | 2 | 3 | 10 | 15 | 30 | 60 | 100 |

| lbf.in | 0.9 | 1.8 | 2.7 | 9 | 13 | 26 | 50 | 90 |

*Not recommended for VortexPro

**Not recommended for HelixaPro

Each sensor is delivered as standard with its own calibration certificate traceable to national standards.

Servicing and calibration

Mecmesin also provides annual servicing and torque sensor re-calibration. Talk to one of our engineers or your local national distributor to find out more.

ETS 0.1 - 0.2

Recommended for HelixaPro only. Fitted with a ¼" female hexagonal drive for connection to grips and test fixtures.

ETS 0.3 - 10

Interchangeable torque sensors for the HelixaPro and VortexPro. Fitted with a ⅜" male square drive for connection to grips and test fixtures.

ETS 15 - 30

For custom applications requiring torque measurement up to 30 N.m, the VortexPro test frame and sensor capacity can be customised to meet your test requirements.

Accessories

Choosing your accessories

It's important that your sample is gripped and held correctly to achieve accurate test results.

Our accessory catalogue contains a wide range of accessories and you should find exactly what you need. Key specifications (such as load rating) are listed on all of our grips and fixtures.

Example test accessoriesKey specs

Torque

Angle

Speed

Axial alignment

Static weights

Dimensions

Common specifications

Software and communications

Key specs

Torque

Available sensors (all measure from zero to the value indicated in the table below)

| Model | ETS 0.1 | ETS 0.2 | ETS 0.3 | ETS 1 | ETS 1.5 | ETS 3 | ETS 6 |

|---|---|---|---|---|---|---|---|

| N.m | 0.1 | 0.2 | 0.3 | 1 | 1.5 | 3 | 6 |

| kgf.cm | 1 | 2 | 3 | 10 | 15 | 30 | 60 |

| lbf.in | 0.9 | 1.8 | 2.7 | 9 | 13 | 26 | 50 |

Accuracy

±0.5% of full scale

Resolution

1:50,000

Units of measurement

mN.m, N.cm, N.m, kgf.cm, gf.cm, ozf.in, lbf.in, lbf.ft

Sampling rate

20 kHz

Data-acquisition rate

1000 Hz, 500 Hz, 100 Hz, 50 Hz, 10 Hz (user selectable)