The MultiTest-dV range integrates perfectly with our VFG Touchscreen Force Gauge, making it a popular configuration for standalone applications that require the capture of a peak load value.

Expand its capabilities by connecting to VectorPro Lite software for presenting data graphically and performing calculations to see test results.

The MultiTest-dV range configured with an Enhanced Load Sensor, VectorPro MT software and an optional extensometer, transforms this motorised force tester into a basic materials tester.

This makes the MultiTest-dV the ideal choice for quality assurance checks in the QC lab and gives it the power necessary for more in-depth analysis of material properties in the R&D laboratory.

The MultiTest-dV is a versatile and easy to use stand-alone force tester.

Ideal for routine quality control in a production or laboratory environment, with three models rated to

A motorised test stand can be configured with a Digital Force Gauge for product testing or an Enhanced Load Sensor for basic materials testing.

Got a question about a product? Your local representative is...

Mecmesin/PPT Group, UK

MultiTest-dV test frame

A ballscrew-driven motorised test frame designed to apply tension and compression from

Its versatile construction makes it perfectly suited for testing all kinds of components in a quality control or R&D environment.

Test frame

The single-column MultiTest-dV features a ballscrew-driven motorised test frame, which is designed to apply tensile and compressive forces from 2N right up to 2.5 kN. There are 3 models in the range with ratings of 0.5 kN, 1 kN and 2.5 kN and offering crosshead travel up to 1200 mm (47").

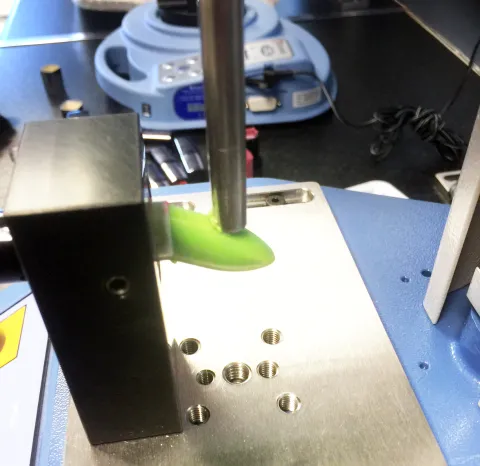

The dovetailed crosshead design ensures operators can quickly and easily attach digital force gauges or ELS loadcells, which are automatically recognised by the software. The base plate of the MultiTest is pre-drilled with threaded holes to directly accept a wide range of grips and fixtures.

Its versatile construction means that the frame has enough daylight to accommodate tall specimens and enough travel to measure the tensile strength of the most elastic of materials.

Data acquisition and plotting

The MultiTest-dV when configured with an Advanced Force Gauge (AFG) optionally enables you to capture test and performance data through VectorPro Lite, but can act as a standalone tester for peak readings.

Connect your computer

The MultiTest-dV requires a Windows PC to run the VectorPro MT software and interact with the ELS loadcell. Its compact design and small footprint make it the perfect selection as a bench-top device.

Force sensors

The MultiTest-dV is a highly flexible tester, which can be configured with either a Touchscreen or Advanced Force Gauge for product testing or an Enhanced Load Sensor for basic materials testing.

AFG

A digital force gauge with advanced features to allow simple control of the MultiTest-dV stand. Excellent accuracy of ±0.1% of the gauge capacity.

ELS

A precision loadcell which connects directly to the MultiTest-dV stand and communicates with VectorPro MT software to allow sophisticated test routines for materials testing applications.

Touchscreen Force Gauge (VFG)

The VFG and AFG range of digital force gauges combine perfectly with the MultiTest-dV to create a flexible, standalone force tester.

To ensure that you have the optimum selection to meet your tension and compression testing needs, ten different models are available to cover the range from 2.5 N right up to 2500 N.

Capacity, range and accuracy

Each gauge reads from zero to its full nominal capacity (listed below).

Measurement accuracy is an outstanding ±0.1% of the gauge capacity, e.g., VFG 100 has a full-scale capacity of 100 N so is accurate to ±0.1 N at any point between 0 - 100 N.

| Model | VFG 2.5 |

VFG 5 |

VFG 10 |

VFG 25 |

VFG 50 |

VFG 100 |

VFG 250 |

VFG 500 |

VFG 1000 |

VFG 2500 |

|---|---|---|---|---|---|---|---|---|---|---|

| N | 2.5 | 5 | 10 | 25 | 50 | 100 | 250 | 500 | 1000 | 2500 |

| lbf | 0.55 | 1.1 | 2.2 | 5.5 | 11 | 22 | 55 | 110 | 220 | 550 |

| kgf | 0.25 | 0.5 | 1 | 2.5 | 5 | 10 | 25 | 50 | 100 | 250 |

Enhanced Load Sensors (ELS)

The ELS range of interchangeable tension and compression loadcells is specially adapted to the MultiTest-dV and OmniTest materials testers.

To ensure that you have the optimum selection to meet your tension and compression testing needs, thirteen different models are available to cover the range from 2 N right up to 2500 N.

The ELS comprises a sturdy mounting box with an internal loadcell c/w small fixing thread and occupies minimal space. The ELS-S comprises the same mounting box with an external S-beam loadcell situated below - it provides a more rigid secure connection for large, heavy grips and fixtures.

ELS capacity, range and accuracy

Each loadcell reads from zero to its full nominal capacity (listed below).

Measurement accuracy is an outstanding ±0.5% of reading from 5-100% of the loadcell capacity, eg ELS 100 when measuring 10N it is accurate to ±0.05 N or when measuring 50N it is accurate to ±0.25 N.

| Model | ELS 2 |

ELS 5 |

ELS 10 |

ELS 25 |

ELS 50 |

ELS 100 |

ELS-S 100 |

ELS-S 200 |

ELS 250 |

ELS 500 |

ELS-S 500 |

ELS-S 1000 |

ELS-S 2500 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N | 2 | 5 | 10 | 25 | 50 | 100 | 100 | 200 | 250 | 500 | 500 | 1000 | 2500 |

| lbf | 0.44 | 1.1 | 2.2 | 5.5 | 11 | 22 | 22 | 44 | 55 | 110 | 110 | 220 | 550 |

| kgf | 0.2 | 0.5 | 1 | 2.5 | 5 | 10 | 10 | 20 | 25 | 50 | 50 | 100 | 250 |

Emperor™ Software

VectorPro® Lite software

Available as an optional extra to Mecmesin’s motorised force testers, VectorPro Lite is an advanced data acquisition and plotting software package. Call-up pre-stored test routines for tensile and compression testing, present test data graphically and issue test reports.

Simply connect the interface cables from your motorised force tester to your PC, and you are ready to enjoy enhanced testing with the power of VectorPro Lite.

Advanced data acquisition, plotting and test storage

Connected to the MultiTest-dV force tester, VectorPro Lite enables the creation, storage and upload of basic test routines. Easily construct flexible operational sequences using a drag and drop interface and built-in version control.

VectorPro Lite captures live tension and compression test values. These values are used to plot a live graph of force vs time/displacement, helping you to visually identify any events during the test that cannot be picked up through just a peak reading on the instrument display.

A suite of standard calculations to help determine whether your sample has passed or failed, with clear pass or fail indicators and operator alerts.

Generate a graphical report with a statistical analysis of results per batch of samples. Reports can be customised and shared as PDF or CSV with your customer.

Accessories

Choosing your accessories

It's important that your sample is gripped and held correctly to achieve accurate test results.

Our accessory catalogue contains a wide range of accessories and you should find exactly what you need. Key specifications (such as load rating) are listed on all of our grips and fixtures.

Example test accessoriesOverview

The MultiTest-dV is a superior motorised force tester offering outstanding value. Designed for precision-controlled compression and tension testing the MultiTest-dV’s simple controls, backed by sophisticated electronics, make it the ideal choice for a wide range of routine testing.

It improves greatly on the variability encountered with manual testers where tension and compression are applied by hand at varying speeds. By applying force at a constant speed, whilst gripping the sample in a uniform manner, the motorised MultiTest-dV significantly enhances the repeatability of test results.

Operators can perform routine batch testing with excellent throughput, minimising testing time, and benefitting from the convenience associated with these motorised tensile testers.

The MultiTest-dV can be configured at two levels:

Simple

Test to a target displacement limit or, when using any one of the Mecmesin range of force gauges—Touchscreen (VFG), Advanced Force Gauge (AFG)—to a load limit or break.

Add VectorPro™ Lite software to a MultiTest-dV with a gauge, for data acquisition, plotting of graphs, calculation of results, plus reporting and exporting of test data.

Sophisticated

Fit a dedicated ELS loadcell and connect up to VectorPro MT software to use your MultiTest-dV as an entry-level materials tester.

Control your whole test sequence with simple, step-by-step programs. Perform both standard calculations like peak, load at displacement and more complex calculations such as Youngs Modulus, and offset yield strength.

Test frame

The MultiTest-dv is a versatile single-column, motorised tester designed for ease-of-use by operators of all levels. There are 3 models in the range with ratings of 0.5 kN, 1 kN and 2.5 kN and offering a crosshead travel up to approx. 1200 mm (47").

Each occupies minimal bench space and are ideal for applying tensile and compressive forces in a variety of applications.

It delivers superior performance via its control panel and multifunctional control wheel, which allows the precise selection of test parameters such as speed and target force/displacement. Coloured LEDs clearly indicate the machine status during testing and operators can effortlessly follow the progress of the test from the force & displacement panel.

For more in-depth recording and analysis of test data, the MultiTest-dV can be connected via its USB output port to VectorPro Lite advanced data-acquisition and plotting software package.

Adjustable safety limit switches are fitted to ensure that specimens cannot be stretched too far or grips crushed together.

The MultiTest-dV is fitted with a dovetailed crosshead for quick and easy interchange of force gauges or loadcells. Grips and fixtures can be rapidly fitted to the anvil plate which is pre-drilled with threaded holes for easy connection.

With no model weighing more than 31 kg (68 lbs), its compact design and small footprint make it an ideal bench-top tester for use in the quality-control laboratory or production area.

Force Gauge

Our digital force gauges are self-contained devices comprising an internal loadcell and its own display. We recommend our VFG Touchscreen or AFG Advanced Force Gauges for use with the MultiTest-dV.

There are 10 models ranging in capacity from 2.5 to 2500 N (0.5 - 500 lbf) each featuring an impressive measurement accuracy of ±0.1% of full-scale.

The gauge is positioned on the crosshead of the test frame via a dovetailed fixing and continuously measures & displays tension/compression, whilst simultaneously capturing the maximum peak readings in the background.

When the gauge is connected to the MultiTest-dV via an interface cable it can transfer the displayed 'live' load reading to the front panel and perform basic control of the test. This is achieved by configuring settings within the gauge to send a signal to the test frame to 'stop' or 'stop and reverse' when a load limit or specimen break is detected.

Tension and compression values obtained by the gauge can be transmitted directly to a PC or printer for the recording of results.

Alternatively, force readings are combined with displacement readings within the MultiTest-dV and sent to the USB output port to create a data-package, which is accessed by VectorPro Lite software for plotting graphs, calculation of results and creation of test reports.

Loadcells

The Enhanced Load Sensor (ELS) is positioned on the crosshead of the test frame and communicates with the MultiTest-dV for precision testing of materials when combined with VectorPro MT software.

There are 13 models ranging in capacity from 2.5 to 2500 N ( 0.5 - 500 lbf) and all are fully interchangeable with their calibration characteristics being immediately recognised by the MultiTest-dV. This ensures that you have the optimum selection to meet all your materials testing needs without the need for lengthy set-up.

Measurement accuracy is an outstanding ±0.5% of reading.

Gripping fixtures

Holding your test specimen in place without it slipping is essential to obtaining repeatable results. Mecmesin have an extensive range of grips and fixtures to hold a variety of components and materials. They include wedge grips and vice grips for tensile testing, compression plates and bend jigs, friction tables plus many more.

Product datasheets

Product Brochures

Key specs

Tension & Compression

Available VFG/AFG loadcells (all measure from zero to the value indicated in the table below)

| Model | VFG 2.5 |

VFG 5 |

VFG 10 |

VFG 25 |

VFG 50 |

VFG 100 |

VFG 250 |

VFG 500 |

VFG 1000 |

VFG 2500 |

|---|---|---|---|---|---|---|---|---|---|---|

| N | 2.5 | 5 | 10 | 25 | 50 | 100 | 250 | 500 | 1000 | 2500 |

| lbf | 0.55 | 1.1 | 2.2 | 5.5 | 11 | 22 | 55 | 110 | 220 | 550 |

| kgf | 0.25 | 0.5 | 1 | 2.5 | 5 | 10 | 25 | 50 | 100 | 250 |

Accuracy

±0.1% of full scale. E.g. VFG/AFG 100 has full-scale capacity of 100 N so is accurate to ± 0.1 N at any point between 0 - 100 N.

Due to the variety of environmental conditions the device may be used in, this value does not include uncertainty of measurement.

Resolution

1:5000

| Model | ELS 2 |

ELS 5 |

ELS 10 |

ELS 25 |

ELS 50 |

ELS 100 |

100 |

200 |

ELS 250 |

ELS 500 |

500 |

1000 |

2500 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N | 2 | 5 | 10 | 25 | 50 | 100 | 100 | 200 | 250 | 500 | 500 | 1000 | 2500 |

| lbf | 0.44 | 1.1 | 2.2 | 5.5 | 11 | 22 | 22 | 44 | 55 | 110 | 110 | 220 | 550 |

| kgf | 0.2 | 0.5 | 1 | 2.5 | 5 | 10 | 10 | 20 | 25 | 50 | 50 | 100 | 250 |

Accuracy

± 0.5% of reading from 5-100% of the loadcell capacity, eg, ELS 100 when measuring 10N is accurate to ± 0.05 N or when measuring 50N it is accurate to ± 0.25 N.

Resolution

1:25,000

Displacement

Maximum crosshead travel (between limit switches)

1186 mm (0.5kN), 986 mm (1kN), 507 mm (2.5kN)

47" (0.5kN), 39" (1kN), 20" (2.5kN)

Accuracy

±0.13mm per 300mm travel (±0.005" per 11.8" travel)

Resolution

0.001mm (0.00004")

Speed

Range

0.1 - 1200 mm/min (0.004 - 47.2"/min)

Accuracy

Better than ±2% of indicated speed or ±20 µ/min, whichever is greater*

* See help.mecmesin.com for additional info.

Resolution

0.1 mm/min (0.004"/min)

Dimensions

Headroom (vertical space to fit sample)

1205 mm (0.5kN), 1005 mm (1kN), 526 mm (2.5kN)

47" (0.5kN), 40" (1kN), 21" (2.5kN)

Throat depth (column to centre-line of gauge)

67 mm (2.6"), 63.5 mm (2.6") with loadcell

Height

1616 mm (0.5kN), 1416 mm (1kN), 941 mm (2.5kN)

64" (0.5kN), 56" (1kN), 37" (2.5kN)

Width

290 mm (11.4") (0.5kN to 2.5kN models)

11.4" (0.5kN to 2.5kN models)

Depth

414 mm (16.3") (0.5kN to 2.5kN models)

Weight

31 kg (68 lbs), 0.5kN; 27.5 kg (61 lbs), 1kN; 24 kg (53 lbs), 2.5kN

Common specifications

Voltage

230 V AC 50 Hz or 110 V AC 60 hz

Operating temperature

10 - 35°C (50 - 95°F)

Humidity range

Normal industry and laboratory conditions, non-condensing

Communications

Output of test results to PC/printer/datalogger

Yes, via USB

Key applications

Got a question about a product? Your local representative is...