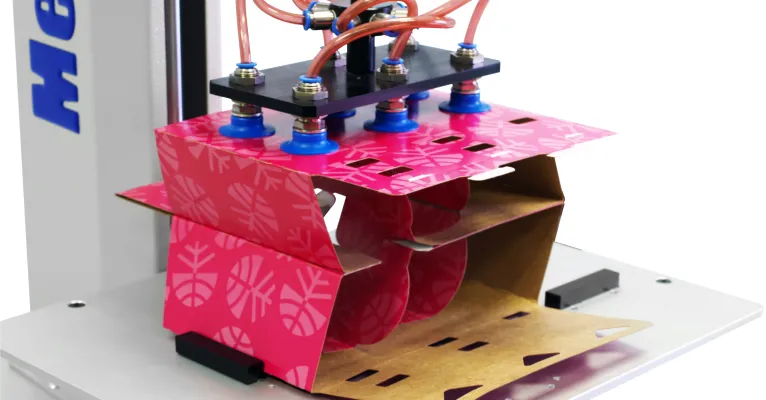

Packaging manufacturers use top-load or crush testing to ensure packaging integrity, and to eliminate material excess while maintaining quality. “Downgauging” or “light-weighting” is a process with high environmental and business significance, since packaging soon becomes waste material, and excess material has powerful cost ramifications.

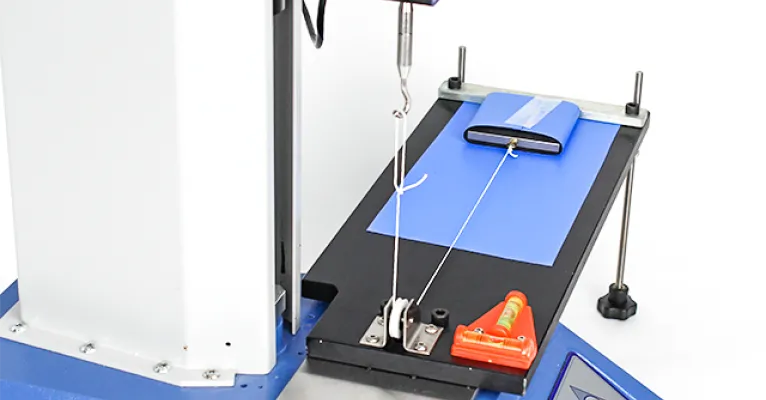

This will be a live, out-of-the-box demonstration where we’ll go through the process of setting up the tester - describing what everything does, programming the unit and running various top-load tests. We’ll then analyze the data and help you interpret the results!

You’ll learn how-to:

- Set-up the tester – describing the major components and what everything does . . .

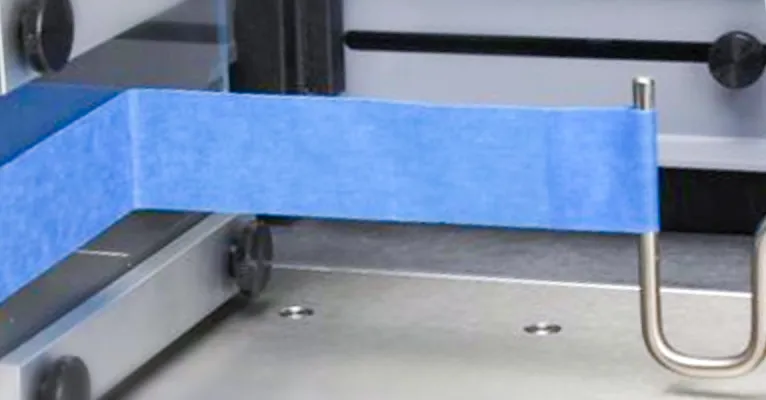

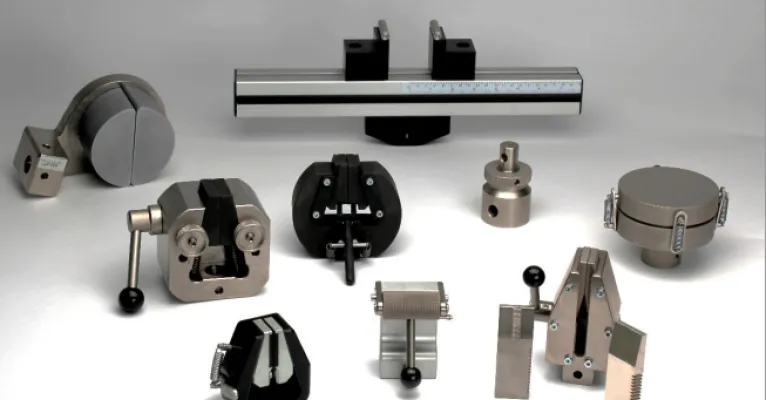

- Select test-appropriate fixtures – vented vs. non-vented compression plates

- Establish Pass/Fail criteria

- Program the tester to measure and record the:

- Force when the container is compressed to a certain displacement

- Deflection when the container is compressed to a known force - Point of deformation or container failure

- Troubleshoot for tester and software errors

- Identify factors that affect data repeatability and consistency

Who should attend?

Design, manufacturing, production, and quality specialists involved in rigid plastic and metal container manufacturing and testing.