In the competitive world of consumer goods, damaged packaging isn't just a financial setback—it can tarnish your brand's reputation.

Customers are far less likely to choose a product with compromised packaging or one that arrives damaged due to inadequate shipping protection. Moreover, most brands are keen to optimize packaging costs by eliminating unnecessary materials without compromising product safety during transit.

In this engaging webinar, we will explore the benefits of packaging testing, helping you understand when, why, and how to test effectively.

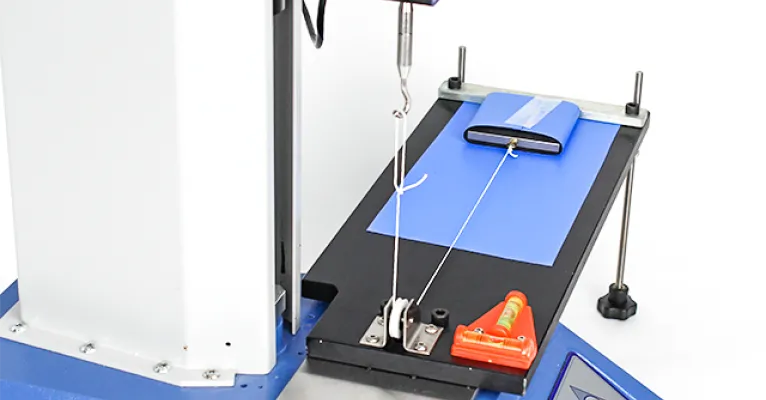

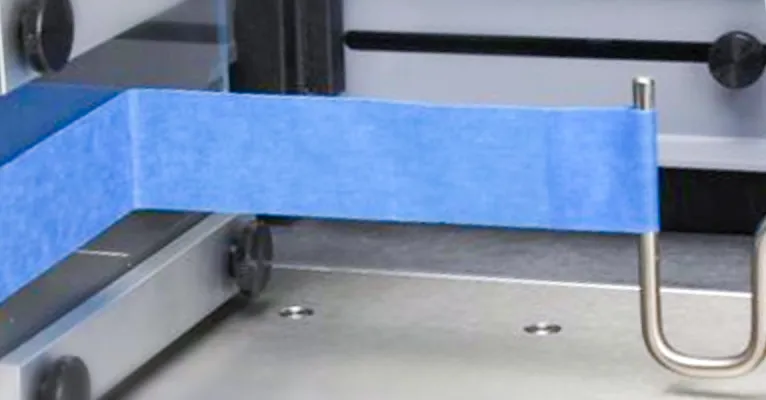

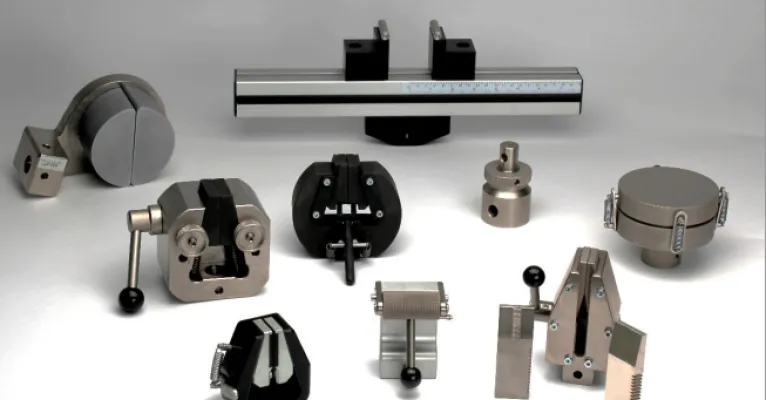

We'll delve into real-world packaging scenarios, covering crucial aspects such as top load resilience, opening torque, peel and tear strength, wear and scratch, box crush resilience, pump actuation, and much more. You'll gain valuable insights into various types of testing equipment used in consumer packaging evaluation and the advantages they offer.

Key Topics:

What, Why, and When to Test (R&D, Production, QC, etc.)?

Typical Packaging Applications:

- Plastic Bottles and Containers

- Caps, Corks, and Stoppers

- Seals and Seams

- Labels and Wrappers

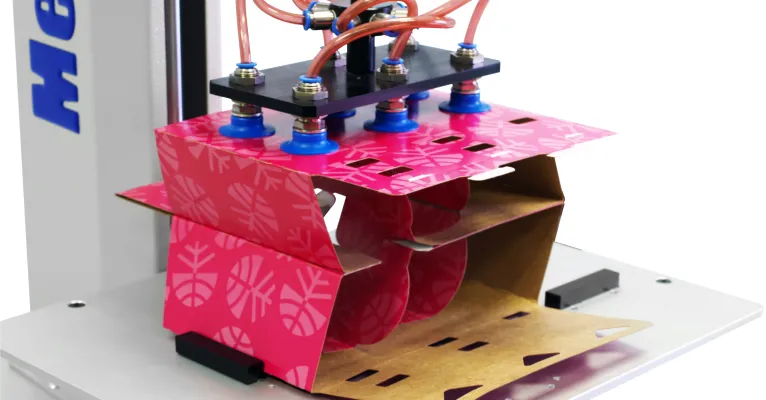

- Cartons and Card

- Dispensing Mechanisms

- Testing Equipment: Force, Torque & Wear Abrasion

Who Should Attend?

This webinar is designed for Manufacturing, Production, and Quality Managers and Engineers involved in various industries, including but not limited to:

- Packaging industry (closures, containers, jars, bottles, tubes – plastic and metal)

- Food and Beverage

- Pharmaceutical

- Medical Device

- Cosmetics

Join us for this session and learn how packaging testing can be a game-changer for your business.