Spring testing in the EMS sector

Solution

- Optimum-capacity software-controlled compression tester

- 5 kN loadcell

Benefits

- Consistent and accurate testing ensures high-quality springs to internal design specifications

- Streamlined testing procedures save time and reduce potential errors

- User-friendly system with software control to implement required procedures

- The safety guard enhances operator safety during testing

Requirement

GPV Asia (Thailand) Co., Ltd. is a leading manufacturer in the metal-forming electronic equipment sector. Their Electronics Manufacturing Services (EMS) operations involve producing high-quality metal products through processes such as forging, pressing, stamping, and rolling. One of their key product lines is springs, which require stringent quality control measures to ensure optimal performance and reliability.

The primary challenge faced by GPV Asia was to acquire a suitably reliable solution for measuring the quality assurance characteristics of their springs.

Maintaining consistent production quality and the ability to enhance specifications when needed was a critical objective. The company set out to elevate the capabilities of their testing equipment and processes to meet these requirements. Specifically, they needed a solution for compression testing to measure the maximum force required to compress the springs to a desired distance, qualifying the stiffness rating, and ensuring they meet internal standards.

Solution

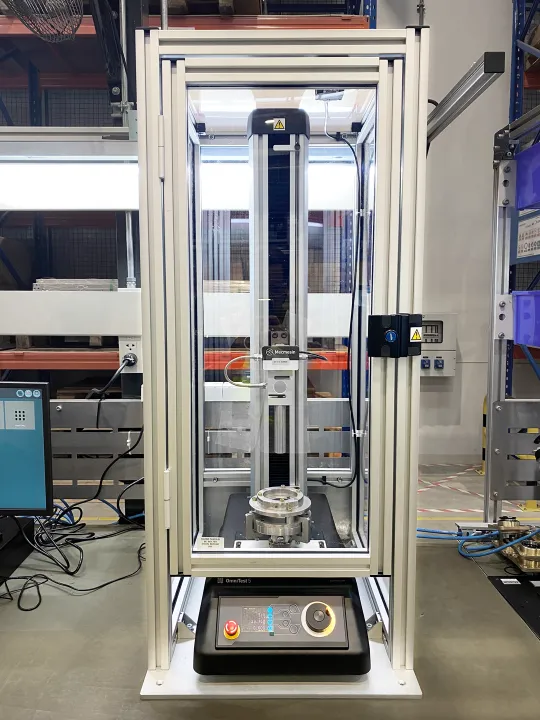

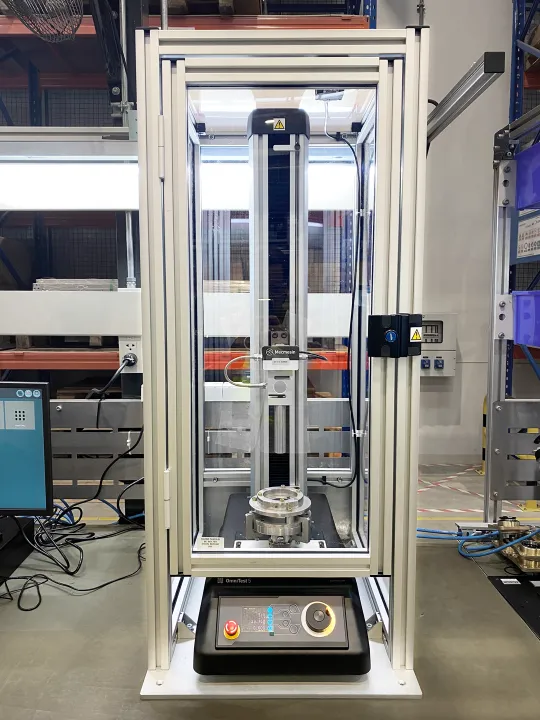

Mecmesin supplied the OmniTest 5, a versatile and precise single-column universal testing machine capable of performing a wide range of compression tests. This compact unit can handle loads up to 5 kN, easily meeting the maximum force specification of a range of helical compression springs. VectorPro software is designed for sophisticated test procedures (if necessary), accurate data analysis and flexible reporting, thus ensuring repeatable and reliable test results. An integrated safety guard ensured operator protection during the testing process with a clear view of the specimen under test.

OmniTest’s ability to accept interchangeable fixtures meant that products of varying geometry could be tested, whilst ensuring that the compression loads were applied axially, and the ends of the springs were seated securely. The OmniTest 5 provides enough vertical test space to accommodate the un-loaded free length of the range of springs manufactured.

Test equipment

- OmniTest 5 kN single-column compression testing machine

- VectorPro software

- High-quality interlocked fitted safety guard

- Company: GPV

- Industry: Electronics, Engineering

- GPV offer a range of services across the high-mix EMS chain, including design and manufacturing